UV Disinfection: The Cutting-Edge Technology Transforming Sanitation Practices

In the realm of cleanliness methods, one modern technology has actually arised as a game-changer: UV sanitation. With its capacity to eliminate harmful microorganisms, this advanced technology is revolutionizing the way we approach sanitation and health. Exactly how does UV disinfection job, and what are the benefits it provides? From health care settings to food processing, UV sanitation is making its mark in numerous markets. In this conversation, we will discover the complexities of this transformative modern technology and expect its encouraging future.

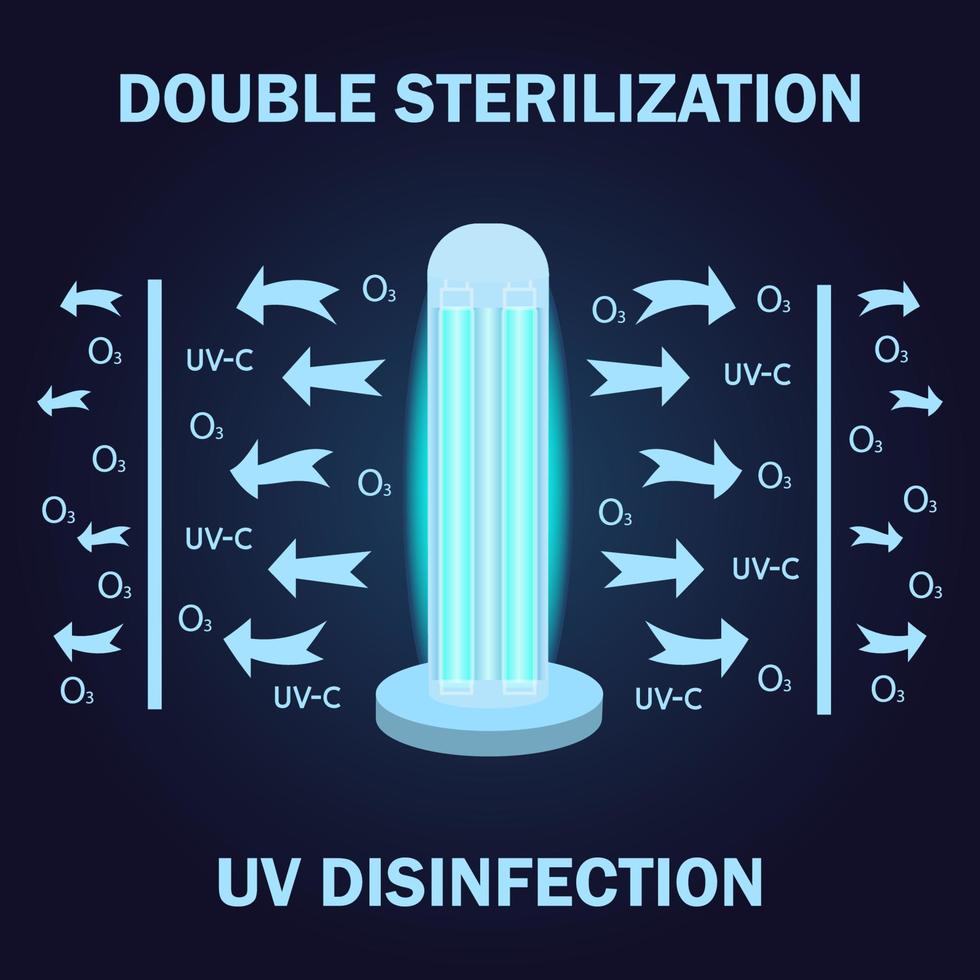

Exactly How UV Sanitation Functions

UV sanitation functions by using ultraviolet light to destroy or inactivate microbes, offering a extremely reliable and chemical-free technique of hygiene. This innovation harnesses the power of short-wavelength UV-C light, which can harming the DNA and RNA of microbes, thus making them not able to cause and duplicate damage.

The process begins with the installation of UV sanitation systems, which include UV lights that emit UV-C light. These lamps are purposefully put in locations where microbial contamination is an issue, such as water therapy plants, healthcare facilities, labs, and food processing centers.

When microorganisms are subjected to UV-C light, the photons penetrate their cell wall surfaces and reach the DNA and RNA within. The high-energy UV-C photons interrupt the hereditary material by developing bonds in between surrounding nucleotides, causing the development of thymine dimers. These dimers stop the bacteria from replicating, rendering them safe.

UV sanitation is extremely effective against a variety of microorganisms, including bloodsuckers, viruses, and microorganisms. It is particularly reliable versus waterborne pathogens like E. coli, Giardia, and Cryptosporidium. UV sanitation is a chemical-free method, removing the demand for potentially dangerous anti-bacterials and decreasing the threat of dangerous disinfection by-products.

Benefits of UV Disinfection

UV disinfection uses numerous benefits in the area of hygiene, making it an extremely preferred approach for efficiently getting rid of hazardous microbes. Unlike standard sanitation techniques that depend on chemicals, UV disinfection makes use of ultraviolet light to destroy the DNA of microorganisms, making them not able to duplicate and trigger infections.

UV sanitation is also highly functional in its applications. It can be utilized in different settings, consisting of healthcare facilities, schools, food handling centers, and water treatment plants. UV sanitation systems can be conveniently incorporated into existing sanitation practices, giving an added layer of protection versus contagious conditions.

Along with its performance and adaptability, UV disinfection is additionally ecologically pleasant. It does not produce any hazardous by-products or residues, making it a sustainable and secure approach for sanitation - uv surface disinfection. Furthermore, UV disinfection calls for marginal upkeep and has a lengthy lifespan, leading to expense savings over time.

UV Disinfection in Health Care Setups

In healthcare settings, UV disinfection has actually emerged as a revolutionary approach for successfully getting rid of damaging microorganisms. UV disinfection works by giving off ultraviolet light at a specific wavelength that is dangerous to bacteria, viruses, and other microorganisms.

First of all, UV sanitation is a non-chemical method, making it an eco friendly option compared to conventional disinfection approaches that often entail making use of rough chemicals. Using UV light eliminates the demand for chemical anti-bacterials, minimizing the threat of unsafe residue or chemical exposure to both clients and medical care employees.

Additionally, UV disinfection is extremely reliable in eliminating a variety of bacteria, consisting of drug-resistant bacteria such as MRSA and C. difficile. It gives a regular and reliable Your Domain Name sanitation process, making sure that all surface areas and devices are completely decontaminated, even in hard-to-reach areas.

UV Disinfection in Food Processing

The application of UV sanitation prolongs beyond medical care setups and locates substantial value in the realm of food handling. uv surface disinfection. UV sanitation technology is ending up being increasingly preferred in the food industry due to its capability to properly remove hazardous pathogens and boost food safety and security

Among the primary benefits of UV sanitation in food handling is its capability to target a vast array of bacteria, consisting of infections, mold and mildews, and bacteria. By utilizing UV light at certain wavelengths, it is feasible to interfere with the DNA and RNA of these microorganisms, providing them not able to replicate or create damage. This technology can be used to numerous phases of the food processing chain, including surface disinfection, devices sanitation, and water therapy.

UV sanitation provides a non-thermal and chemical-free technique of sterilizing foodstuff. Unlike typical sanitation approaches that depend on chemicals or heat, UV technology does not leave any type of deposit or change the taste, appearance, or nutritional worth of the food. This makes it a perfect option for industries that need stringent adherence to official website quality criteria.

In addition, UV sanitation systems are simple to operate and mount, calling for very little maintenance. They can be incorporated right into existing handling lines without causing substantial interruptions to the production procedure. In addition, UV systems have a quick treatment time, permitting for constant handling and lowering downtime.

The Future of UV Sanitation

One area where UV sanitation is expected to make considerable advancements is in the field of medical care. With the increase of antibiotic-resistant germs and the requirement for more efficient sanitation methods, UV light has the prospective to play an essential function in decreasing healthcare-associated infections. UV disinfection systems can be used to decontaminate surfaces, devices, and even the air in medical care facilities, helping to stop the spread of unsafe pathogens and enhance person safety and security.

One more sector that might take advantage of improvements in UV sanitation innovation is the food industry. UV light has already shown to be a reliable approach for sanitizing food and decreasing the danger of foodborne health problems. As innovation boosts, we can expect to see extra cost-effective and effective UV disinfection systems being carried out in food processing plants, making certain that the food we take in is risk-free and without harmful microorganisms.

Final Thought

In conclusion, UV sanitation is a sophisticated modern technology that is changing sanitation practices in medical care setups and food handling. By using UV light to kill or deactivate bacteria, it supplies countless benefits such as efficiency, security, and performance. With recurring advancements in this area, UV sanitation holds terrific potential for the future of hygiene, offering a lasting and reputable solution for maintaining tidy and hygienic environments.

UV sanitation is a chemical-free technique, getting rid of the demand for possibly unsafe anti-bacterials and minimizing the risk of dangerous disinfection byproducts.

Unlike standard disinfection approaches that count on chemicals, UV sanitation makes use of ultraviolet light to destroy the DNA of microorganisms, making them incapable to duplicate and cause infections. Unlike conventional sanitation methods that rely on chemicals or heat, UV technology does not leave any type of deposit or alter the preference, structure, or dietary value of the food. As modern technology improves, we can expect to see much more economical and reliable UV disinfection systems being implemented in food handling plants, making sure that the food we eat is risk-free and cost-free from unsafe microorganisms.

In verdict, UV disinfection is a sophisticated technology that is transforming cleanliness methods in healthcare setups and food processing.